Ever since the invention of the corrugator over one hundred years ago, the corrugator belt has remained relatively unchanged; until now!

The result of over ten years of research and development using the combined talents of the world leading textile engineers, boxmakers and corrugated equipment engineers has led to SPIRABELT, a top corrugator belt of unparalleled design and function that was recently awarded various patents.

Traditionally, top corrugator belts have been comprised of either a multi-layer woven or woven-needled structure. These old designs have several inherent weak points: they are heavy, requiring considerable energy to drive them; they have a very low permeability, trapping moisture in the board; they require the use of mechanical seams, which have a tendency to wear and cause sheet mark; finally, they can be difficult to keep clean, requiring additional maintenance and expense to prevent debris from marking the board or futher impending the permeability. Spirabelt was specifically created to address these issues and more!

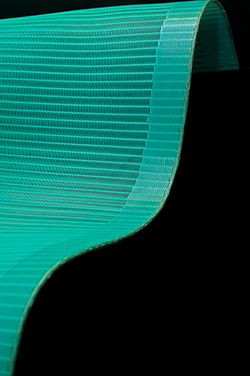

Spirabelt is a dramatic departure from traditional belt designs. Manufactured from only one raw material, its unique structure is made of helically wound bands of monofilament share arranged side-by-side in longitude, are interlaced and then connected by monofilament linking pins. The monofilaments are custom manufactured from a special chemically hardened thermoplastic that is both heat and abrasion resistant. These monofilaments are then formed into helical bands and assembled using highly specialized equipment, under the highest tolerances in our state of the art ISO Certified production facilities.

The spiral construction eliminates the needs for multiple layers of yarns and fibres that eventually wear down causing board delamination. Once installed, Spirabelt is completely seamless, eliminating the need of traditional metal hooks and flaps or flocking. Spirabelt also has an exceptional surface profile ensuring no sheet marking while enabling over one hundred times more air permeability than woven or needled belts.

Supported by numerous independently verified field studies, Spirabelt has been documented and proven to provide users with measurable improvement in board caliper and reduced warp. Users also observe a decrease in paper waste both at the double backer and at converting thanks to a flatter and perfectly conditioned board. Furthermore Spirabelt is the only corrugator belt proven to provide a considerable reduction in double-backer drive amperage consumption with shoe type pressing systems.

Always ensuring our customers receive optimal results, Spirabelt is supported by technical engineers dedicated to corrugators. We understand our customer's needs and provide them with the most qualified level of support available. In return, our customers have been fervent about spreading the news of a product that consistently delivers on promised quality improvements while reducing operating costs and board waste.